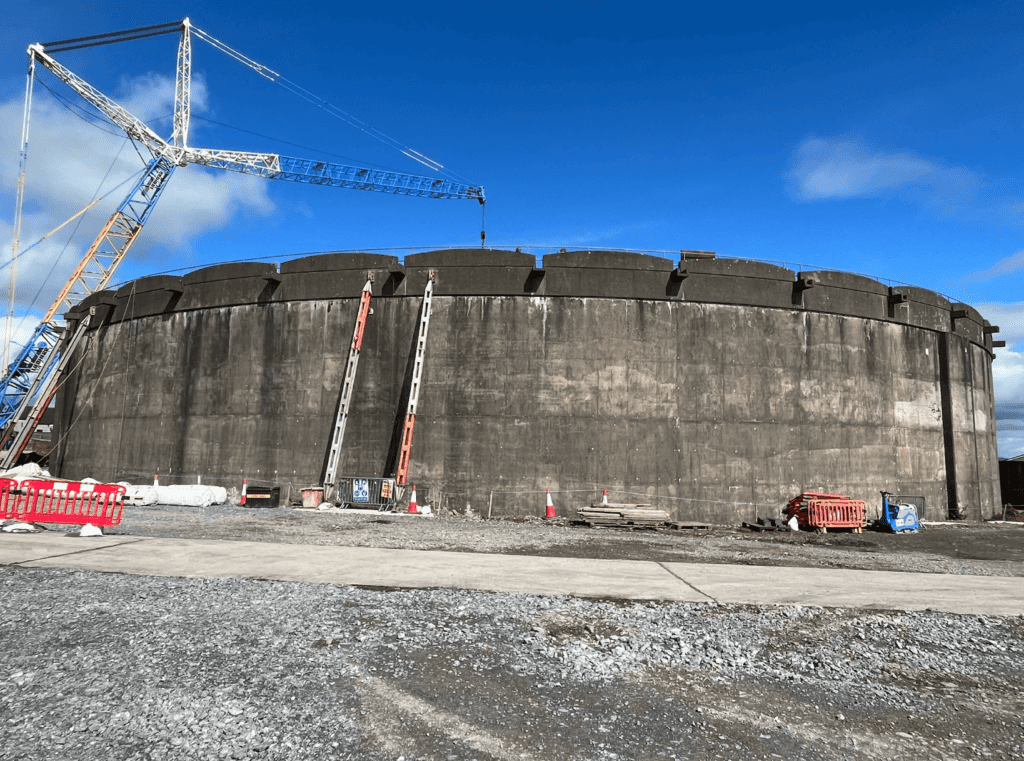

LONDON HEATHROW AIRPORT HILTON HOTEL

Case Studies / LONDON HEATHROW AIRPORT HILTON HOTEL

PROJECT SUMMARY

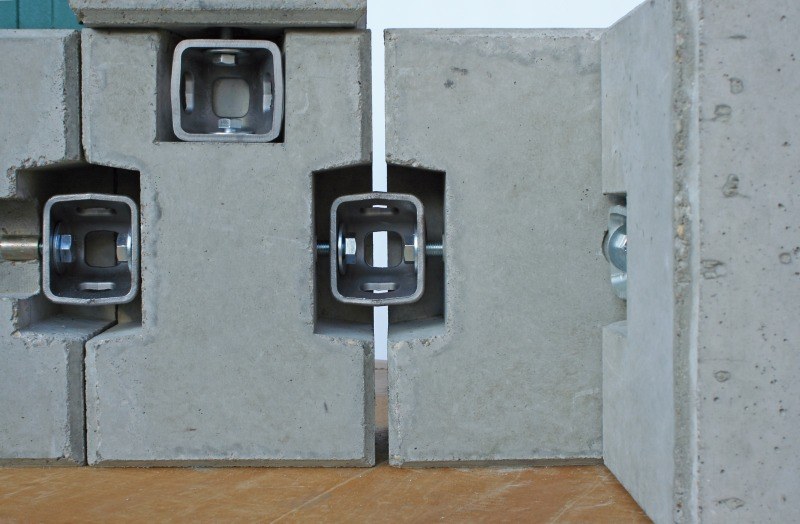

BT Innovations Turnbuckle was used in the assembly of the outer wall elements which were manufactured and assembled by O’Reilly Concrete Group. They installed a total of 1,200 BT Turnbuckles – four per outer wall element.

OUR SOLUTION

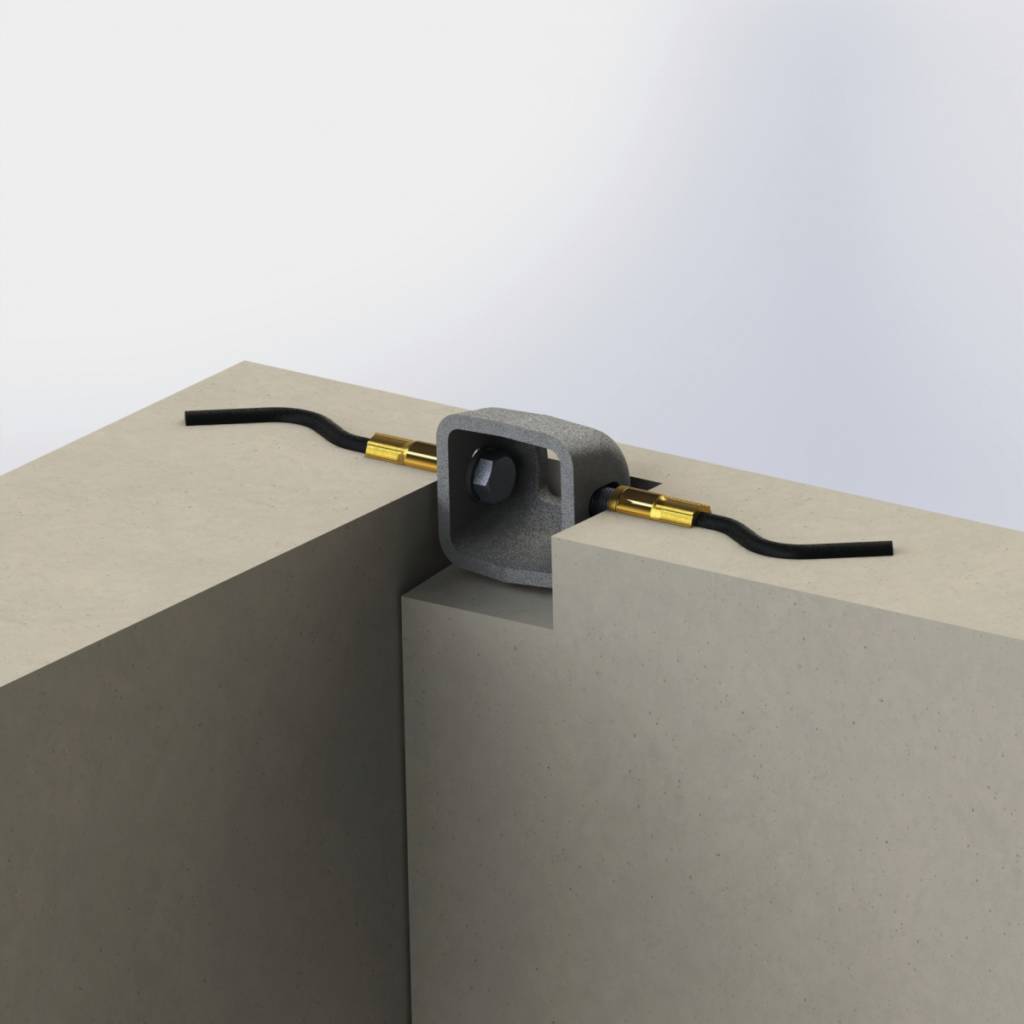

The Turnbuckle acting as part of a tensioning system that includes bolted joints and anchors recessed in the precast concrete elements. It enables the economical, simple, precise assembly and permanent structural connection of precast concrete elements. In the case of predominantly static loads in the pulling and shear directions.

For more information on BT Turnbuckle and projects we have worked on across UK and Ireland, please contact our technical team on +44 (28) 3752 8999 or [email protected]

Share this post