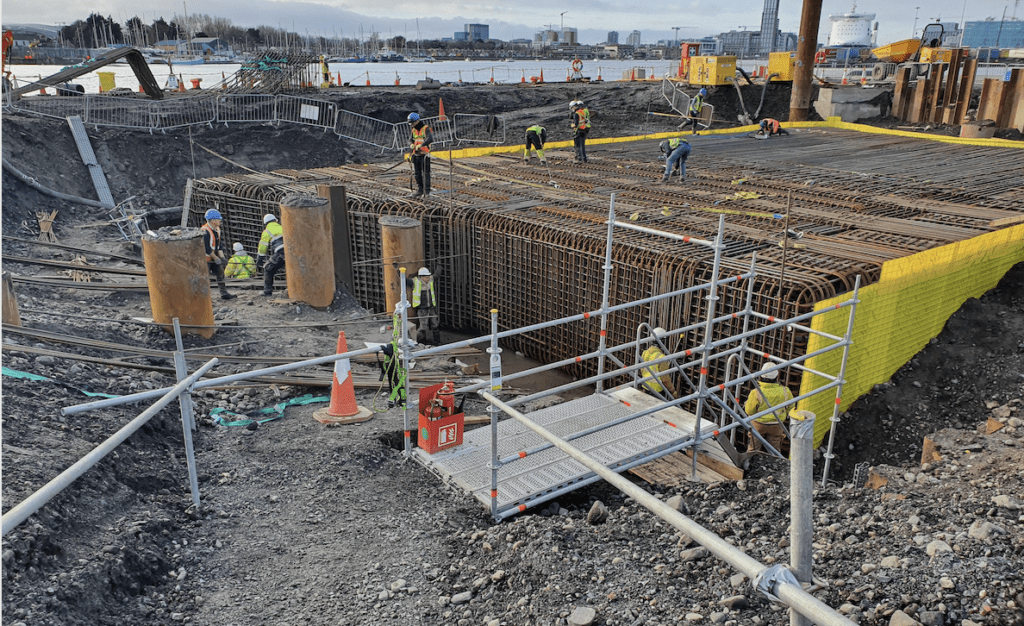

OCEAN PIER BERTH 35 PECAFIL INSTALLATION

Case Studies / OCEAN PIER BERTH 35 PECAFIL INSTALLATION

Customer

Roadbridge

Project

Redevelopment of Ocean Pier Berth 35

Project Summary

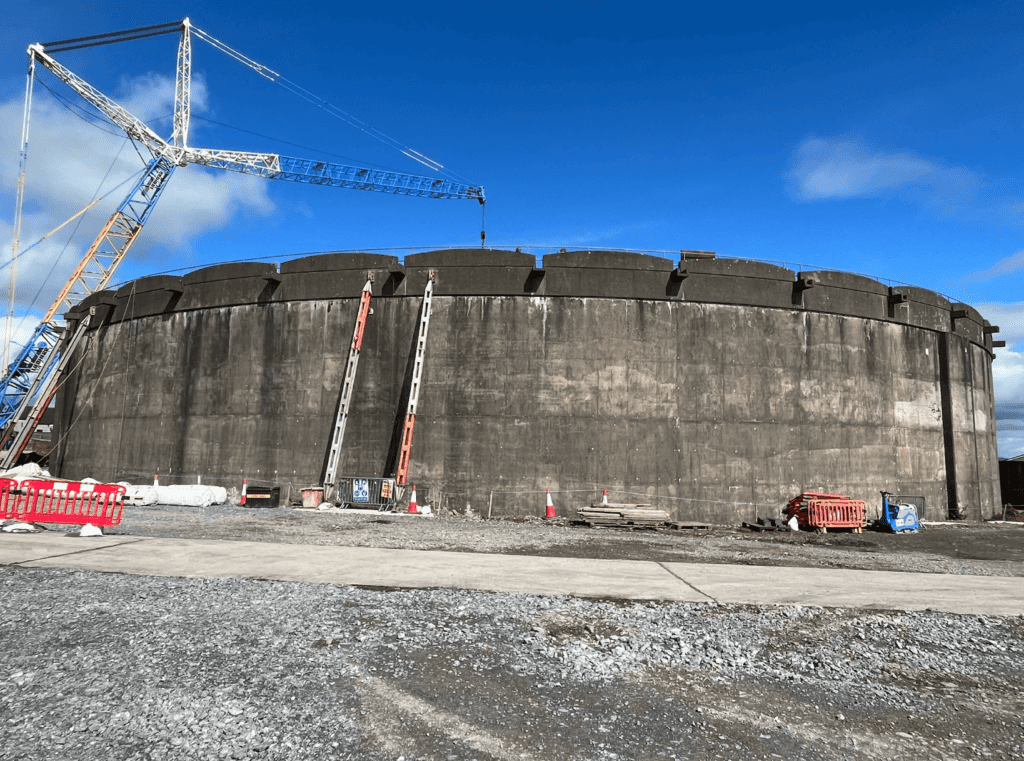

The project includes 133m of new combi-pile quay wall, and over 5000m² of apron slab.

Roadbridge along with their JV partner Keating Construction successfully completed Framework One for Dublin Port Company which included 720m of new quay wall constructed between 2017 and 2020.

Our Solution

SDG, being a long-standing partner of Max Frank Group were tasked with the supply of the Max Frank Pecafil® system.

Permanent formworks systems such as Pecafil offer a time saving and cost-effective method of constructing reinforced concrete foundations compared to the traditional erect, prop and strike shuttering methods.

Benefits of Pecafil:

- Reduced working space requirements

- Minimal overdig and cartaway

- Offsite fabrication of panels

- No specialist trades required

- Concrete saving

- Potential to eliminate concrete blinding

- Faster method of construction

Share this post