SEAQUEST SYSTEMS – SYLOMER® INSTALLATION KILLYBEGS

Case Studies / SEAQUEST SYSTEMS – SYLOMER® INSTALLATION KILLYBEGS

Date of Construction

May 2021

Client

SeaQuest

PROJECT SUMMARY

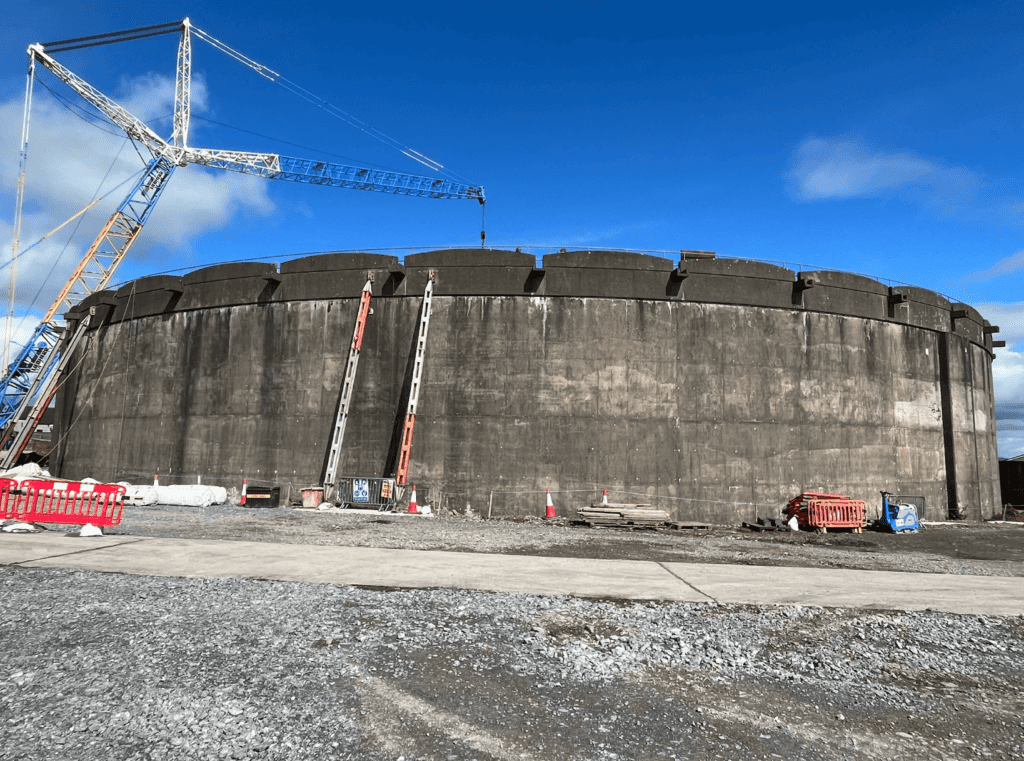

SeaQuest Systems are a Killybegs based marine engineering company leading the way in the design and manufacture of fish pumps and hydraulic systems for offshore vessels. As a growing manufacturer, SeaQuest reached out to

SDG requesting expert assistance on vibration control for a new 50-tonne boring machine. SeaQuest recognised the need to protect the buildings structure from the vibrations caused by the new machine.

THE CHALLENGE

As with all industrial settings, vibration isolation is a key issue which needs addressed at the design stage of any new machine install.

Vibration reduction is crucial for several reasons:

• It protects sensitive machinery and reduces wear and tear

• It reduces sound generation, thereby protecting operatives

• Prevents unwanted machinery movement

• Stops vibrations which may affect the quality of the product being produced

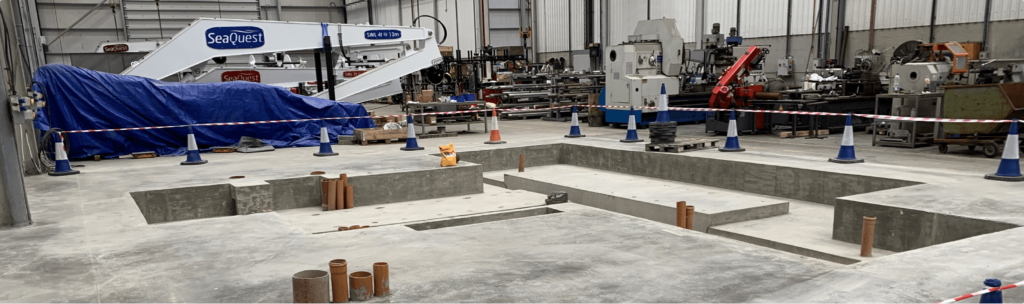

SDG were tasked with coming up with a product proposal which would carry the weight of the 50-tonne machine and slab, along with reducing its impact on the immediate environment.

OUR SOLUTION

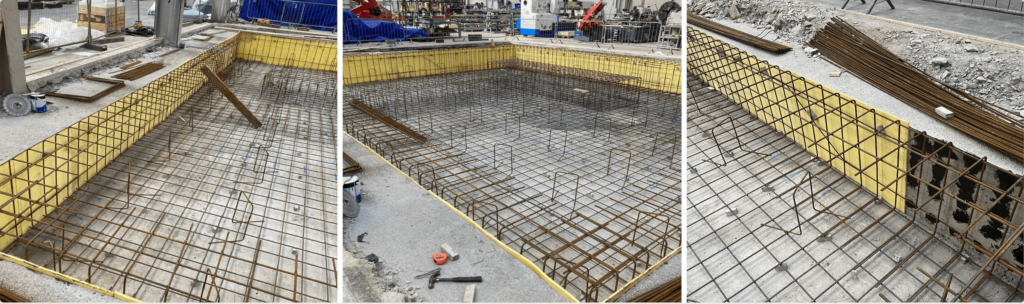

Our team supplied Sylomer® (elastic mixed cellular polyurethane material), this unique material provides an elastic layer of insulation between the vibration source and the protected surface.

Sylomer® is a leading material in the vibration isolation market, working to reduce vibrations and noise, while reducing maintenance costs.

SDG were tasked with coming up with a product proposal which would carry the weight of the 50-tonne machine and slab, along with reducing its impact on the immediate environment.

By isolating the side walls of this machine base with Sylomer®, it efficiently reduced the transmission of vibrations from the surroundings into the structure.

Share this post