Preventing Rising Damp in Masonry

Why is rising damp a concern for building owners?

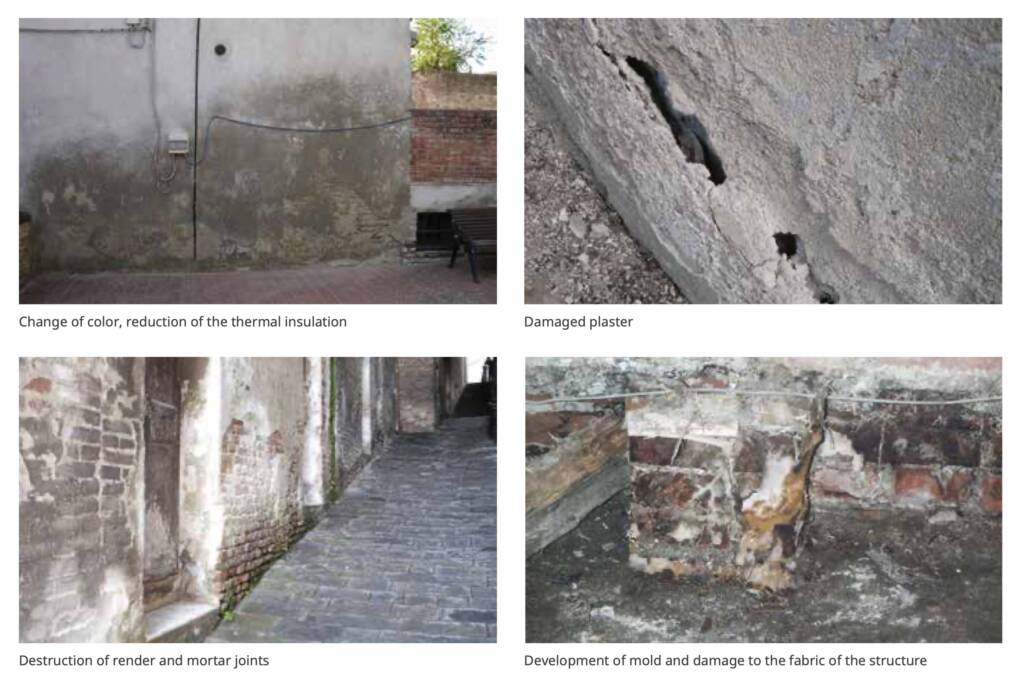

Over time rising damp in combination with salt contamination and / or frost can destroy masonry structurally. Taking into account the decrease of the remaining lifespans of such buildings, rising damp causes high financial damage every year.

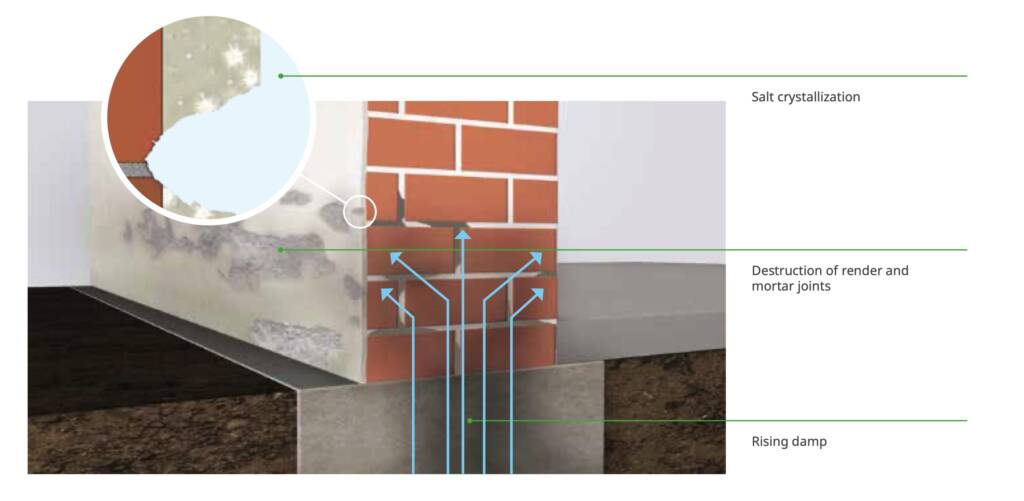

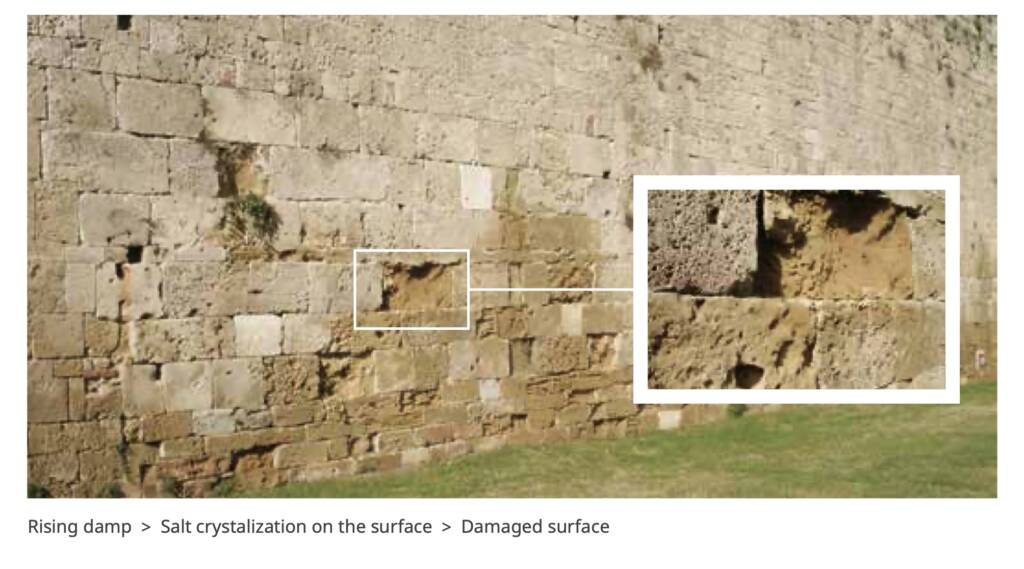

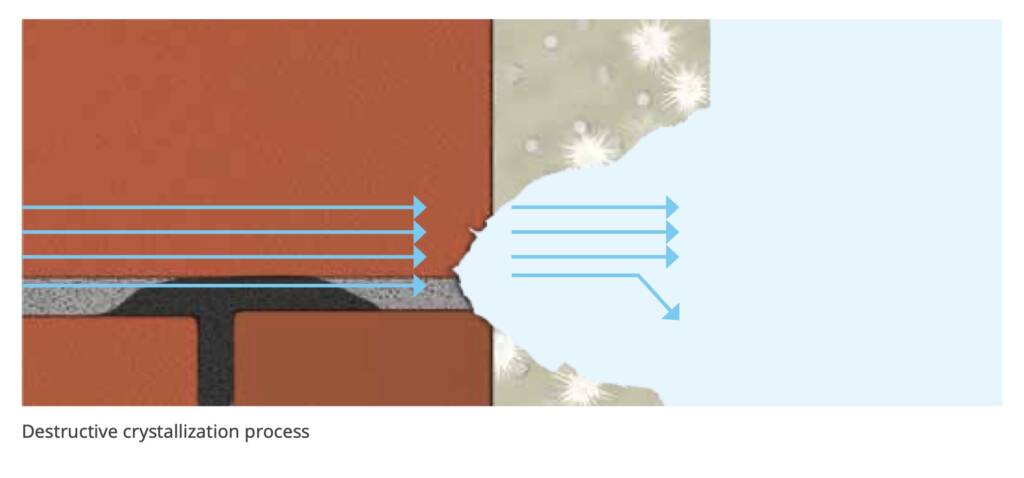

Rising damp can cause significant structural damage to masonry over time, especially when combined with salt contamination and frost. As moisture travels upwards through the capillaries, it evaporates on the surface, leading to an accumulation of salts. This process is most pronounced in the transition zone between the dry top and damp bottom of the wall, where signs of damage are often first observed. Due to the cumulative effects of rising damp, masonry structures can deteriorate over time, leading to high financial costs for repairs and maintenance.

How does rising damp damage masonry?

In masonry that is affected by rising damp, moisture is continuously transported upward through the capillaries. The water evaporates on the surface and more moisture follows. This process will usually lead to an increase in the concentration of salts on the surface. Most evaporation occurs between the dry (top) and the damp part of the wall (bottom). In these areas, there are often the first signs of damage.

Over time, rising damp can cause significant structural damage to masonry, especially when combined with salt contamination and frost. As moisture travels upwards through the capillaries, it evaporates on the surface, leading to an accumulation of salts. This process is most pronounced in the transition zone between the dry top and damp bottom of the wall, where signs of damage are often first observed. Due to the cumulative effects of rising damp, masonry structures can deteriorate over time, leading to high financial costs for repairs and maintenance.

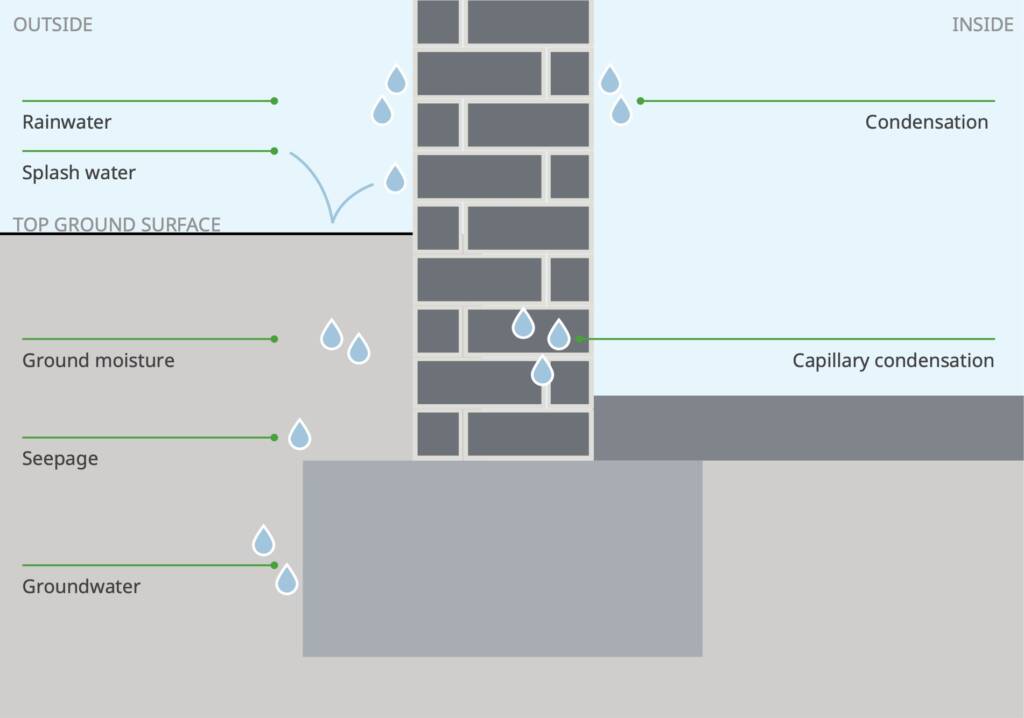

Where does the water come from?

The origin of water in masonry walls can be traced to various sources such as rainwater, groundwater, and condensation. Leaks in gutters or drainage pipes can also contribute to water penetration. When the water entering the wall is not adequately drained or dispersed, it can be continuously transported through the capillaries of the building material. This process, known as “rising damp,” occurs as the water rises upwards against gravity through capillary action.

Is it rising damp?

Before undertaking any renovation measures on a wall exhibiting damage that may be attributed to rising damp, it is essential to have it analysed by a specialist to determine the root cause. Several factors such as the type of damage, building characteristics, salt and moisture content of the building materials, and other potential sources of water infiltration must be considered when devising repair strategies. It is important to note that rising damp may not always be the cause of damage, as other factors such as splashing water above a functional horizontal barrier, hygroscopic action, or leaking pipes can also be responsible. In cases where rising damp is determined to be the root cause, a restoration plan should consider the salt and moisture content of the building material, and a salt and moisture analysis is recommended to inform the restoration approach.

Why does moisture rise in masonry?

Moisture rises in masonry due to the combined effects of cohesion (surface tension of the liquid) and adhesion (interfacial tension between the liquid and the solid surface). When a liquid, like water, comes into contact with a surface, it has the tendency to spread. However, the surface tension of water counteracts this tendency. Building materials, such as bricks and concrete, contain small pores that absorb water in a way similar to a sponge. Depending on the size of the pores, water can be transported upwards against gravity, a process known as rising damp. Pores with a diameter between 0.0001 mm and 0.1 mm, called capillaries, are responsible for the most significant water transport in building materials. Between 20% and 50% of the pores in materials like concrete, brick, and mortar fall into this category. Capillaries with smaller diameters generate higher capillary pressure, resulting in greater capillary elevation. For instance, a capillary with a diameter of 1 μm (0.001 mm) can produce a suction pressure of 1.5 bar, equivalent to a capillary elevation of water of around 15 m. It’s worth noting that the size of pores below 0.0001 mm (micro-pores) is too small for capillary water transport, whereas pores above 0.1 mm are too large.

What have salts got to do with rising damp?

Water that is transported through a wall typically contains salts, which can originate from various sources, such as ground moisture, groundwater, or the brick itself. The presence of salts in the water can cause an increase in salt concentration in the wall when the water evaporates on the surface. This leads to the formation of salt crystals in the pores of the building material, which can cause an increase in volume and high strength of the crystals. Over time, this process can lead to the destruction of the pores and the surface of the construction material can become brittle and start to fall off.

Frost can have a similar effect as the ice crystals that form during freezing have a larger volume than the liquid water in the pores. This expansion of ice crystals builds up high pressure that can ultimately result in the destruction of the building material.

How can rising damp be stopped?

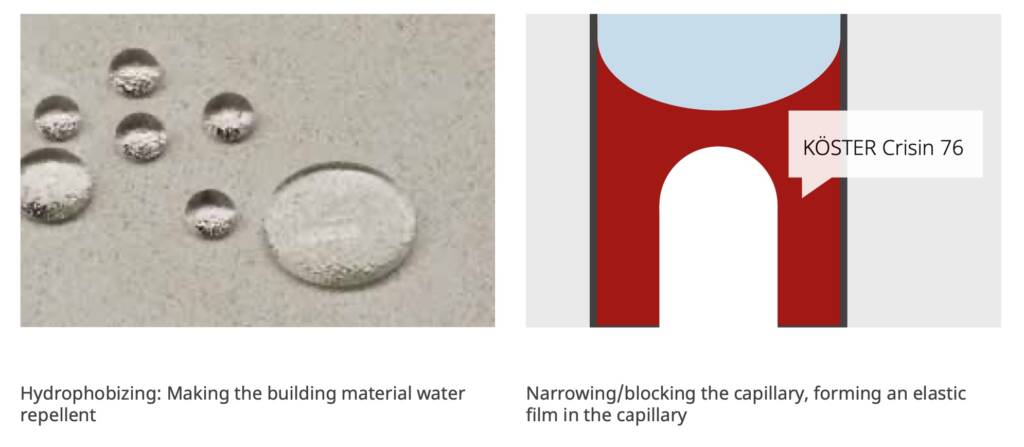

To prevent rising damp, there are two primary methods: one involves blocking pores that are capable of capillary action, while the other involves making the structure of those pores hydrophobic. Hydrophobization of a pore surface refers to modifying its surface tension to become water-repellent, thus halting its capillary action. Blocking a pore involves filling it partially or completely to stop water transport. It is essential to add enough material into the pore to narrow its diameter sufficiently to prevent any further capillary action.

KÖSTER Crisin 76 stops rising damp with the following effects: It first lines the capillaries with a water repellent film. In the next step it narrows the pore diameter to the extent that the capillary action cannot take place anymore. The combination of these effects together ensure that KÖSTER Crisin 76 works every time, regardless of the pore structure, salt or moisture content. It penetrates deeply into the smallest capillaries in building materials and permanently stops capillary action.

Due to the hydrophobic effect of KÖSTER Crisin 76, the drying process in the wall begins immediately, creating an active horizontal barrier as soon as the system has been installed.

The patented KÖSTER Suction Angle System is the result of decades of experience and development work by the KÖSTER BAUCHEMIE AG. The horizontal barrier is distributed through the capillary transport itself, stopping the rising damp with its own physical cause.

The KÖSTER Capillary Rod acts like a wick, one end is inserted into the wall and the other end into the KÖSTER Suction Angle. From there, it draws the injection liquid into the wall. The KÖSTER Capillary Rod is available in lengths of 45 or 90 cm.

This is a crucial advantage not only when installing horizontal barriers into hollow bricks, vertically perforated bricks or old and cracked masonry, but also for all other conditions. The method is clearly visible and allows easy control of the distribution of the injection material into the wall. It also gives security in the cost calculation for the installation of a horizontal barrier since the amount of material needed can be easily and accurately determined (the flow of the material is achieved through the rods and therefore there is no possibility of material run off).

Advantages of KÖSTER Crisin 76

- suitable even in cases of high moisture contents up to 95 %

- suitable regardless of salt content

- suitable for a variety of salts such as sulphates, nitrates, and chlorides

- solvent free

- the treated substrate does not have to be alkaline for the material to react

- no prior mechanical drying of the wall is necessary, even in case of high moisture contents

- no subsequent drying is needed

- resistant against most ordinary aggressive substances that are encountered in masonry such as acids, alkalis, and salts

- fast reaction, immediately effective

- not bio-degradable

- does not cause or promote corrosion of steel reinforcement

- does not cause or promote corrosion of steel reinforcementdensity (0.91 g/cm3); penetrates deeply even into the smallest capillaries of the

- construction material the cured material and as a result the horizontal barrier itself is elastic and can be applied to perforated brick and cracked or hollow masonry without the necessity of void filling

- no subsequent injection is necessary, one-time installation, is guaranteed success

- patented system

- easy installation, horizontal drilling

- the material ́s action principle is proven to be effective for more than 30 years

- does not mix with water

- 10 years warranty

KÖSTER Crisin 76 ist chemically neutral and does not cause efflorescence. It is furthermore resistant against most ordinary aggressive substances that are encountered in masonry such as diluted acids and alkalis.

Share this post