Advanced Formwork Solutions: Exploring Stremaform® Permanent Formwork

Stremaform® is a leading product in permanent formwork solutions, designed to streamline the construction process for working joints in concrete installations. Developed and perfected over 30 years by Max Frank, a partner of SDG, Stremaform® formwork solutions are engineered to remain in place after concrete pours, forming a part of the permanent structure. This innovative approach eliminates the need for dismantling and disposal, offering a sharp contrast to traditional timber formwork solutions.

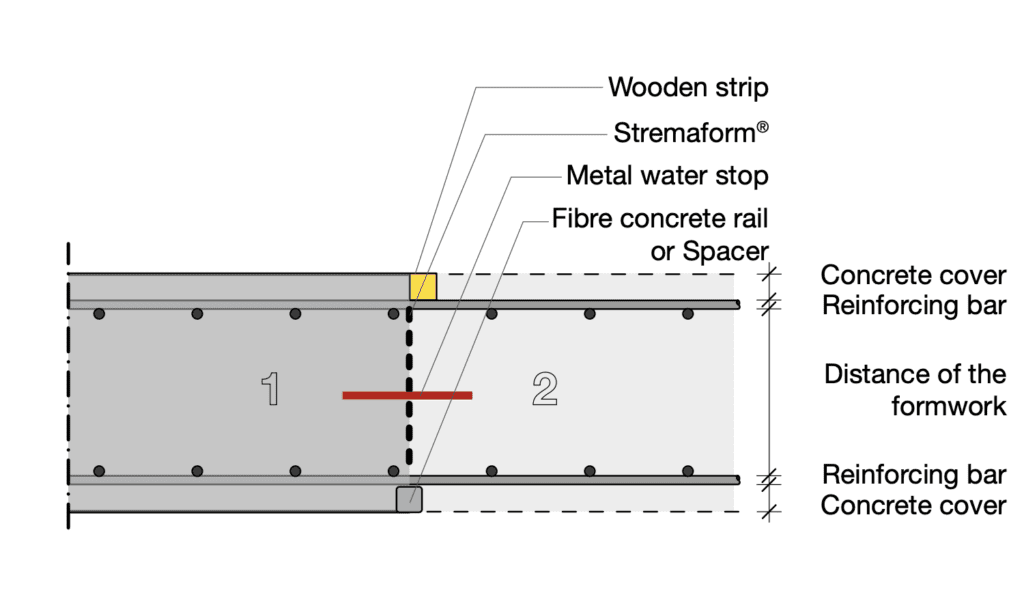

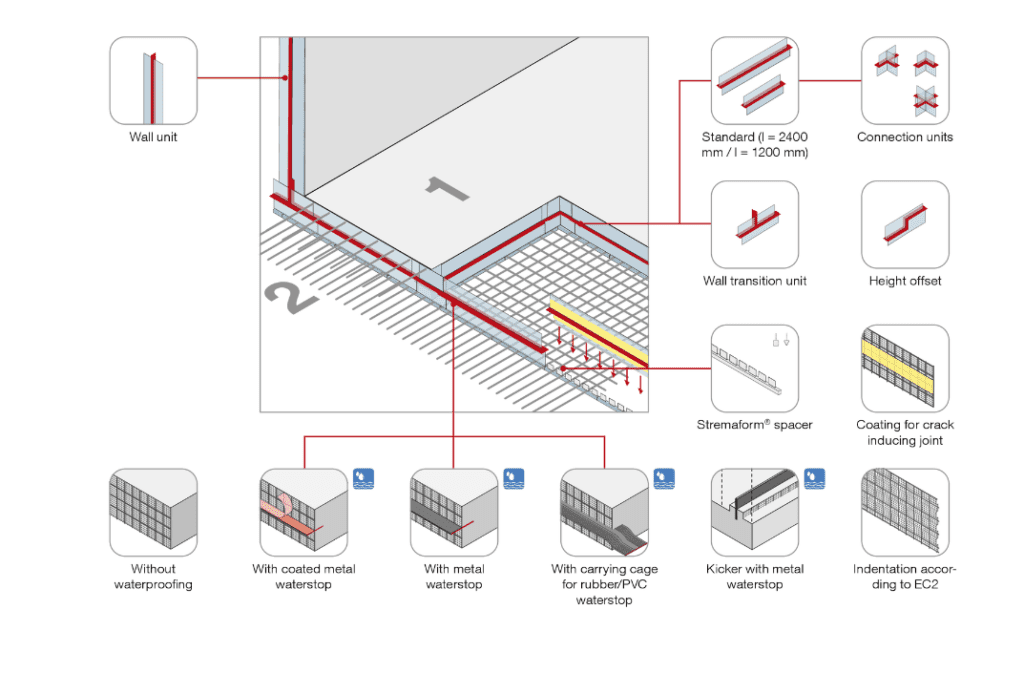

The system comprises various configurations, including options with integrated water stops and crack control features, which are crucial for maintaining the structural integrity and waterproofing of concrete assemblies. These formwork elements are particularly beneficial in constructing floor slabs, ceilings, and walls, where precision and durability are paramount.

Utilising Stremaform® enables formworkers to achieve faster construction timelines and reduced labour costs, as this formwork solution is pre-fabricated and ready to install. The result is a more efficient building process, lower overall project costs, and minimised effort on site, making Stremaform® an ideal choice for modern formwork demands.

What is Stremaform®?

Stremaform® is a formwork solution designed to be permanently integrated into concrete structures, facilitating the creation of working joints in construction projects. It is prominently used in the floors, walls, and ceilings of various structures, marking significant advancements in formwork technology.

Types and Applications

The product line includes several variants tailored to specific needs:

Stremaform® strong

Stremaform® strong formwork solutions elements are of similar construction as Stremaform® flat material but with added reinforcement girders. The size and positioning of girders can be arranged to accommodate any wall thickness or slab depth. The use of back bracing means that these formwork elements are self-supporting when installed in accordance with our Guidelines.

Stremaform® with indented joint

All Stremaform® formwork elements can be manufactured with one or more indented joints.

The standard indented joint meets the requirements of DIN EN 1992-1-1.

■ The geometry of the indented joint can be tailored to your layout specifications

■ Indented joint and factory stiffening (Stremaform® strong) can be combined

■ All elements can be supplied with an integrated metal water stop or rubber waterbar cage

Stremaform® with metal water stop

All Stremaform® formwork elements can be supplied with a metal water stop. The jointing plate is available in standard widths of 250 mm or 300 mm or according to your specifications. To prevent void formation under the metal water stop during concrete placement, the water stop can be angled upwards by 15º on both sides.

Stremaform® with PVC/rubber water bar cage

All Stremaform® formwork elements can be supplied with a rubber water bar cage for on-site installation of a rubber water bar. The rubber water bar cage is available in standard widths of 200 mm, 250 mm and 320 mm. Other dimensions are possible. To prevent void formation, a rubber water bar cage with both sides angled upwards by 15° can be supplied.

Click here to find out about other product variations.

These variants cater to different structural requirements, ensuring flexibility and adaptability in diverse construction scenarios. Each type is crafted to meet the highest standards of durability and performance, characteristic of German engineering excellence.

Engineering and Manufacture

Engineered by Max Frank in Germany, Stremaform® formwork elements incorporate high-quality materials and are constructed to precise specifications. This ensures seamless integration into concrete slabs and walls, optimising structural integrity and simplifying the construction process.

Formwork Solutions: Comparative Analysis of Stremaform®

Comparison with Traditional Formwork Solutions

Stremaform® sets itself apart from traditional timber formwork through its stay-in-place design, eliminating the need for removal post-concrete pour. This comparison highlights two main areas:

Efficiency: Traditional formwork solutions require multiple steps—assembly, disassembly, and often cleaning and storage for reuse. Stremaform®, being a permanent part of the structure, saves time and labour by cutting out these steps.

Durability and Safety: Timber formwork can degrade over time and with exposure to the elements, potentially leading to safety risks. Stremaform® is made from durable materials that integrate seamlessly with concrete, enhancing the structural integrity and longevity of the installation.

Advanced Features of Stremaform®

Stremaform® incorporates several innovative features that enhance its utility in construction projects:

Integrated Water Stops: Options include metal and rubber water stops to prevent leakage, a critical feature in below-grade and water-exposed structures.

Pre-Fabricated Customisation: Each unit is tailor-made to specifications, ensuring a perfect fit and reducing the need for onsite adjustments.

By offering a more streamlined, safer, and customisable approach to formwork solutions, Stremaform® provides a superior alternative to traditional methods, making it an ideal choice for modern construction projects looking for efficiency and reliability.

Call our team today to find out how Stremaform® can help your next project or click below to find out more on the product.

Stremaform®?

Stremaform® is a permanent formwork system used in the construction of concrete structures. It is designed to stay in place after the concrete has set, forming an integral part of the finished structure. This system is typically used for creating working joints, controlled crack joints, and expansion joints in concrete slabs, walls, and ceilings.

Share this post