Breaking Thermal Bridges with Egcobox®

SDG know how important it is to use quality materials that promote energy efficiency in buildings. Now more than ever, building occupants expect energy-efficient structures that promote healthy indoor environments. This means minimising issues like high heating bills, cold drafts, condensation, and mould growth. When architecturally planning new buildings, special attention should be given to breaking thermal bridges throughout the building envelope. Strategies like balcony thermal breaks are an important piece of creating a comfortable, energy-efficient building that meets user expectations.

One of the products we supply from Max Frank, is Egcobox® – an innovative thermal break for balconies and other applications. In this blog post, we’ll discuss the benefits of thermal breaks like Egcobox® and how they help prevent heat loss in concrete construction.

Egcobox – breaking thermal bridges

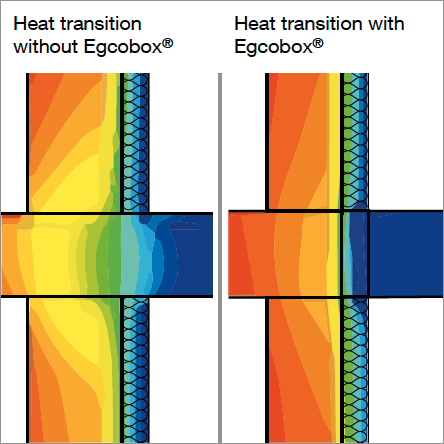

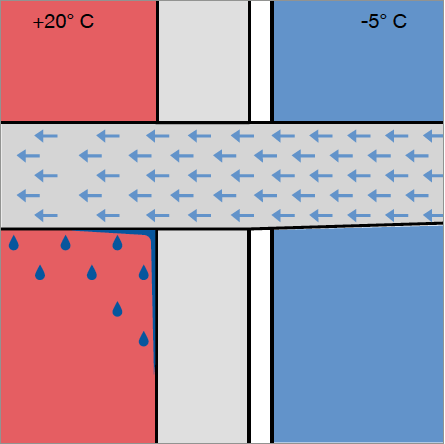

When two parts of a building that are at different temperatures meet each other, this forms what is known as a thermal bridge. As concrete is a conductor of heat, places where the interior concrete structure meets the exterior facade tend to allow heat to escape. This heat loss is exaggerated at balconies and other cantilevered parts of a structure.

Why Thermal Breaks Are Essential

Breaking Thermal bridges can account for up to 30% of a building’s heat loss. This wasted energy is not only bad for the environment, but it also costs owners and residents more in heating bills. Thermal bridges also create cold spots in a structure that can lead to condensation and mould growth.

Installing thermal breaks helps eliminate these issues. Thermal breaks are made of materials that are poor heat conductors. They create a separation between the inner and outer layers of concrete to “break” the thermal bridge.

How Egcobox® Works as a Thermal Break

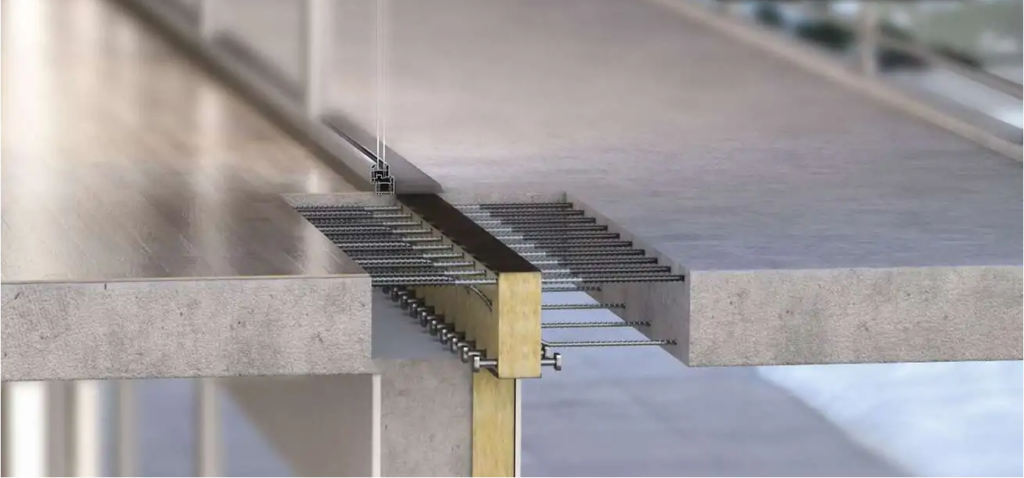

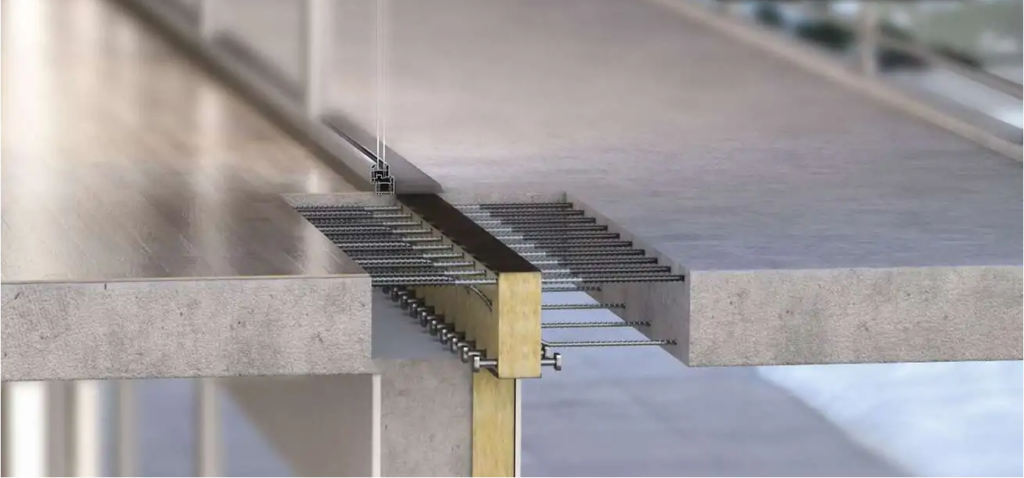

Egcobox® from Max Frank is an ingenious thermal break system designed specifically for balconies in concrete construction.

The structural function of the Egcobox® elements is provided by a bar framework

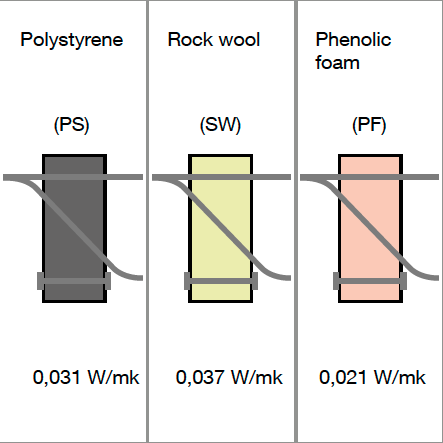

made of reinforcing steel, which is passed through the thermal insulation that is usually 80 to 120 mm thick. Depending on the project requirements, Egcobox can be manufactured with any of the following insulation materials:

- Polystyrene 0.031 W/mK

- Rock wool 0.037 W/mK

- Phenolic foam 0.021 W/mK

Thermal bridges

Condensation

Heat transition coefficient of the thermal insulation

Impact sound protection

The Egcobox® elements have three key benefits:

Insulation: The glass fibre-reinforced material provides effective insulation between the balcony slab and the rest of the structure. This prevents heat loss through the balcony.

Load Transfer: While insulating, Egcobox still allows load transfer to meet structural requirements. The balcony remains securely attached.

Fire protection: The fire protection requirements of balconies and cantilevered components are governed in the respective building regulations. The fire protection of the Egcobox® cantilever connectors can be ensured with different versions. This depends on the insulating material selected for the Egcobox ® elements.

Thermal Breaks for Energy Savings

Adding thermal breaks is becoming a standard part of energy-efficient building. Products like Egcobox® deliver proven performance and make it easy to reduce thermal bridging.

As your trusted suppliers, we’re proud to offer Egcobox® and other innovative solutions from Max Frank. Contact us to learn more about how thermal breaks can benefit your next construction project.

Share this post