Introduction to Pecafil® Permanent Formwork

Pecafil® Permanent Formwork, a pioneering solution in the construction industry designed for versatility and efficiency, changing the way contractors and formworkers approach complex construction tasks.Pecafil® Permanent Formwork, a pioneering solution in the construction industry designed for versatility and efficiency, changing the way contractors and formworkers approach complex construction tasks.

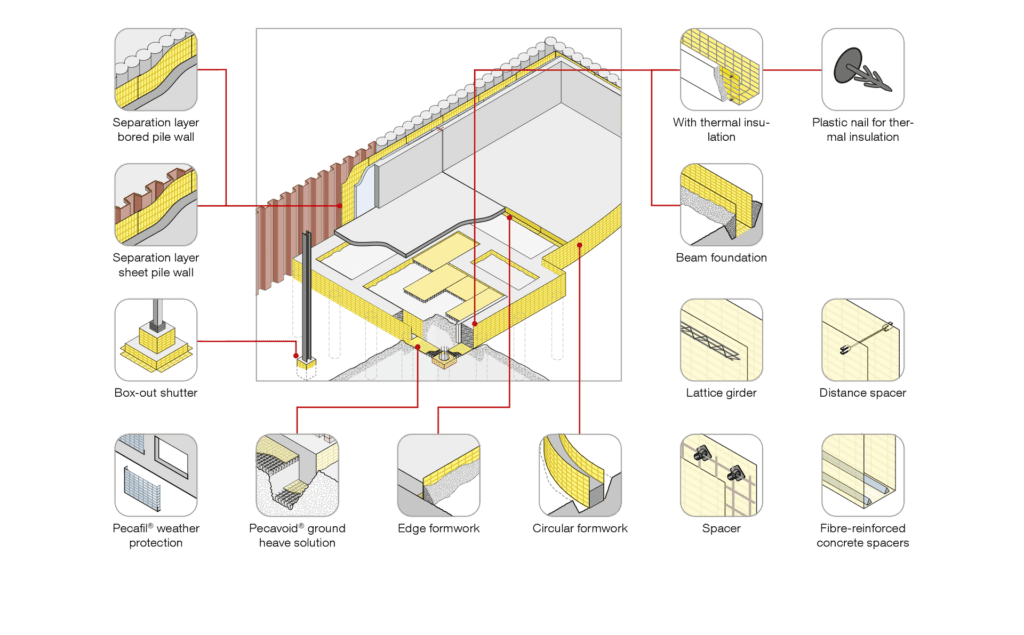

With its unique material properties and ease of use, Pecafil® offers a reliable alternative to traditional formwork methods, enhancing project timelines and reducing labour costs. Ideal for a range of applications including strip and sleeve foundations, edge formwork, separation formwork, ribbed slabs and much more, it’s becoming a go-to choice for forward-thinking construction professionals throughout Ireland and the UK.

Versatility and Applications of Pecafil® Permanent Formwork

This innovative solution provides exceptional versatility, catering to a wide array of construction requirements. Whether it’s forming foundations, creating ribbed slabs, or facilitating complex geometries, Pecafil® adapts effortlessly to various construction scenarios. Its adaptability not only streamlines the construction process but also opens new possibilities for innovative design and execution in building projects. This flexibility is a significant advantage for contractors and formworkers, allowing them to tackle diverse construction challenges with greater efficiency and creativity.

Technical Support and Tailored Solutions of Pecafil® Permanent Formwork

To provide fast and accurate formwork Pecafil® comes with a comprehensive detailing service to match the supply of standard and custom manufactured elements to your exact requirements.

Either call SDG to talk through your requirements or we can arrange a site visit. Based on your site drawings and discussions our technical team and Max Frank specialists will produce a detailed Pecafil® design scheme that will provide the optimum formwork solution for your project. This not only saves you money through reducing material waste on site but ensures that formwork is quick and easy to install.

Max Frank will manufacture any shaped components within 24 hours of your order confirmation and supply both standard and shaped components. All units are individually marked and are supplied along with a fully detailed schedule of the units where necessary to simplify installation.

The support and services offered for Pecafil® are comprehensive, ensuring that contractors and formworkers have access to expert guidance and customisation options.

Pecafil® Product Specifications

Pecafil® is produced in a wide range of sheet and strip sizes, with various wire diameters and mesh centres to suit the specific application.

- L – shaped units are ideal for wide, shallow beams or rectangular bases.

- Circular formwork can be created to virtually any size with radiuses units.

- U – section ground beam units provide a fast and efficient way to construct beams in a clean lined excavation.

- U – sections are also suitable to form the perimeter of semi-raft foundations and different side heights are also easily produced. Pecafil® is the concrete saving solution for semi raft foundations in less stable ground conditions such as mining areas, flood plains, landfill sites or where peat or clay are present.

- Factory cut and bent shapes can be formed to exact concrete outlines making Pecafil® ideal to construct pile caps or bases –simply fix the spacers to the reinforcement cage and position the Pecafil® units.

Ease of use and Installation of Pecafil®

The ease of use and installation of Pecafil® is a major advantage for formworkers and contractors, offering significant benefits in terms of time and labour savings. Its design allows for quick and straightforward handling and can be easily shaped and placed on-site, reducing the time typically associated with traditional formwork installation. This efficiency in installation not only saves valuable labour hours but also accelerates project timelines, a crucial advantage in a fast-paced construction environment.

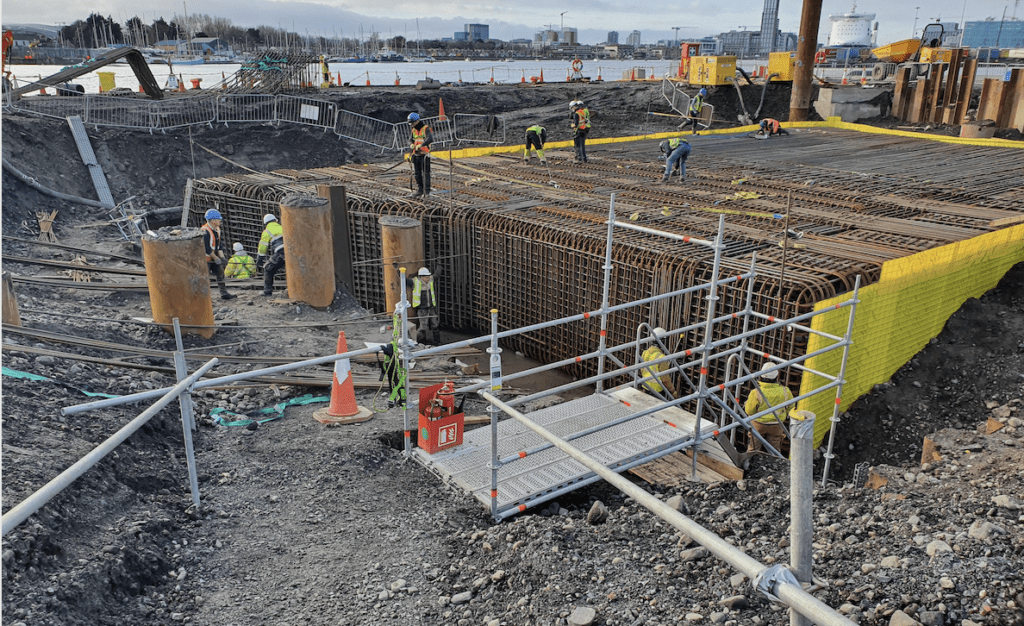

Project

The Dublin Port Project stands as a testament to the efficiency and versatility of Pecafil®. Undertaken by Roadbridge and Keating Construction, this project involved creating 133m of new quay wall and over 5000m² of apron slab. The use of Max Frank Pecafil® system, supplied by SDG, highlights its effectiveness in large-scale projects.

The project showcased several benefits of Pecafil® including reduced workspace requirements, minimal excavation, prefabricated panels, no need for specialist trades, concrete savings, and a notably faster construction method.

Manufacturing of Pecafil®

The manufacturing process of Pecafil® permanent formwork by Max Frank is marked by its innovative approach and high-quality standards. The product, which has been refined over 30 years, is produced in a modern Max Frank facility where coils of steel wire are transformed into specially manufactured mesh. This mesh is then encapsulated within a high-grade polyethylene foil membrane, ensuring durability and resistance to concrete pressure. This process, including the use of a non-toxic, UV-stabilised membrane, results in a product that is not only strong and durable but also easy to handle and install.

Environmental Impact and Sustainability

Pecafil® demonstrates a strong commitment to sustainability, which is a crucial aspect for the construction industry in throughout Ireland and UK. Its manufacturing process emphasises environmental responsibility, producing a product that is recyclable, groundwater neutral and made from recycled material. This focus on sustainability not only aligns with current environmental standards but also appeals to the growing eco-consciousness within the construction sector. By choosing Pecafil®, contractors and formworkers are not only opting for an efficient construction solution but are also contributing to a more sustainable building environment.

Pecafil® represents a forward-thinking solution in the construction industry. We encourage contractors and formworkers to consider Pecafil® for their next project, to experience first-hand its benefits in terms of time-saving and adaptability. Adopting Pecafil® could be a significant step towards more efficient and eco-friendly construction practices.

To find out more or to download the technical brochure:

Planning a new project that involves construction accessories such as Formwork Solutions, Formwork Accessories, Permanent Formwork, Concrete Deck and Wall Spacers, Structural Waterproofing and much more? SDG offers an extensive range of construction accessories tailored for your specific requirements.

Get in touch with our team for more information on our products or to schedule a consultation. Our expert team are committed to assisting you throughout your project’s journey, ensuring its successful and efficient completion.

Share this post