Efficient Formwork Systems Transforming Precast Manufacturing

In the dynamic and ever-evolving construction industry, the demands placed on concrete as a building material have significantly increased. Today, construction methods have transformed, embracing new shapes, colours, functions, and innovative applications.

To keep up with these changing requirements, it is essential to adopt advanced processing techniques and modern formwork systems. In this blog, we will explore the benefits and solutions offered by BT Innovations’ formwork systems, including Multiform and Multiform Alu, in the precast manufacturing industry.

The Evolution of Formwork Systems:

Traditionally, the construction of wooden formwork has been a time-consuming and costly process. This approach requires extensive resources and results in long production times.

However, BT Innovation offers a ground-breaking solution that minimises these efforts, revolutionising the formwork construction landscape.

Understanding Formwork Systems:

Formwork technology has become an indispensable part of the construction industry. A concrete form serves as a special mould into which fresh concrete is poured to produce various types of concrete components. Once the concrete has hardened, the formwork is removed, revealing the finished product.

The formwork plan defines the component’s geometry and dimensions, while the subsequent formwork plan details the construction process.

Optimising Production with BT Innovation:

BT Innovations’ formwork systems streamline the production process, offering practical and time-saving solutions for modern concrete construction and formwork technology. Their high-quality and innovative applications cater specifically to precast concrete elements.

Introducing Multiform: A Game-Changer in Formwork Construction:

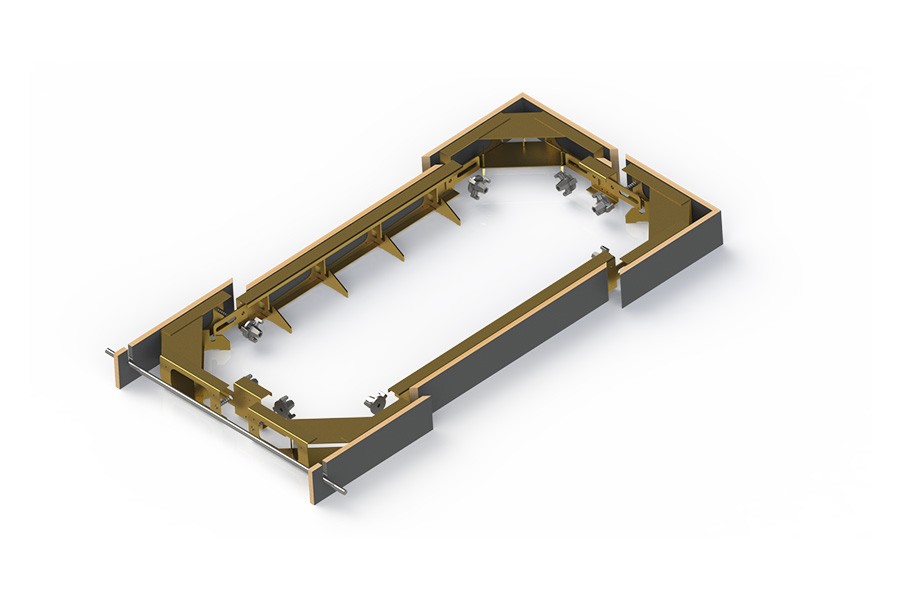

BT Innovations’ Multiform system exemplifies the company’s commitment to excellence. This system features MagFly® magnets, which facilitate easy movement and precise positioning of the formwork on the control table.

By employing a PE triangular strip, the MagFly® AP MultiForm presses onto the switch table, sealing the joint immediately upon magnet activation.

This eliminates the need for subsequent sealing with silicone, enhancing efficiency and reducing labour-intensive tasks.

Ingenious Solutions with MultiForm:

The MultiForm system offers a clever solution for enclosed openings such as windows and doors within concrete components. The formwork includes elements that can be dismantled inwards, enabling non-destructive stripping and reusability.

Moreover, the integrated receptacle for MagFly® magnets ensures fast and precise assembly and disassembly of the formwork, further optimising the construction process.

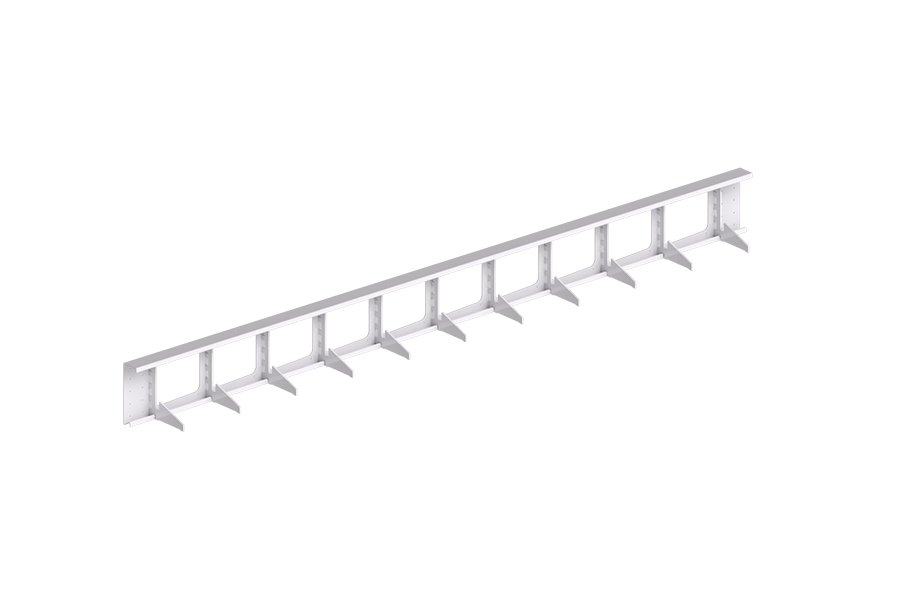

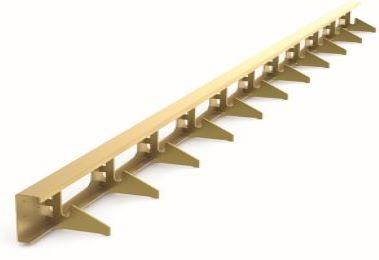

Introducing MultiForm Alu: Lightweight and Sturdy Formwork Beam:

In addition to Multiform, BT Innovation also offers MultiForm Alu, a lightweight yet dimensionally stable and sturdy formwork beam. Constructed from specially coated aluminium, MultiForm Alu is designed to meet the needs of the modern construction industry.

Its innovative features provide strength and reliability while significantly reducing weight and simplifying handling processes.

BT Innovations’ formwork systems, including Multiform, MultiForm Alu and Multiform Window & Door Recess, have revolutionised the precast manufacturing industry.

BT Innovation has successfully addressed the challenges faced by modern construction methods, their high-quality, practical, and time-saving solutions enable Precast manufacturers to achieve exceptional results while minimising costs and maximising efficiency.

Embracing these innovative formwork systems will undoubtedly enhance the future of the precast manufacturing industry, paving the way for limitless possibilities in concrete construction.

Share this post