Looking to Securely Seal Concrete Joints? Try Hydrophilic Waterstops

SDG provide intelligent waterproofing systems for reinforced concrete structures. A key product in our range is hydrophilic waterstops. These provide an effective solution for sealing construction joints susceptible to water ingress.

What are Hydrophilic Waterstops?

Hydrophilic waterstops are joint sealing profiles typically made of bentonite or thermoplastic elastomer (TPE) hydrophilic materials. They have a rectangular cross-section and come in rolls of varying lengths depending on the profile size. The hydrophilic material has a molecular structure that attracts water molecules and absorbs liquid through hydrogen bonding.

How Do Hydrophilic Waterstops Work?

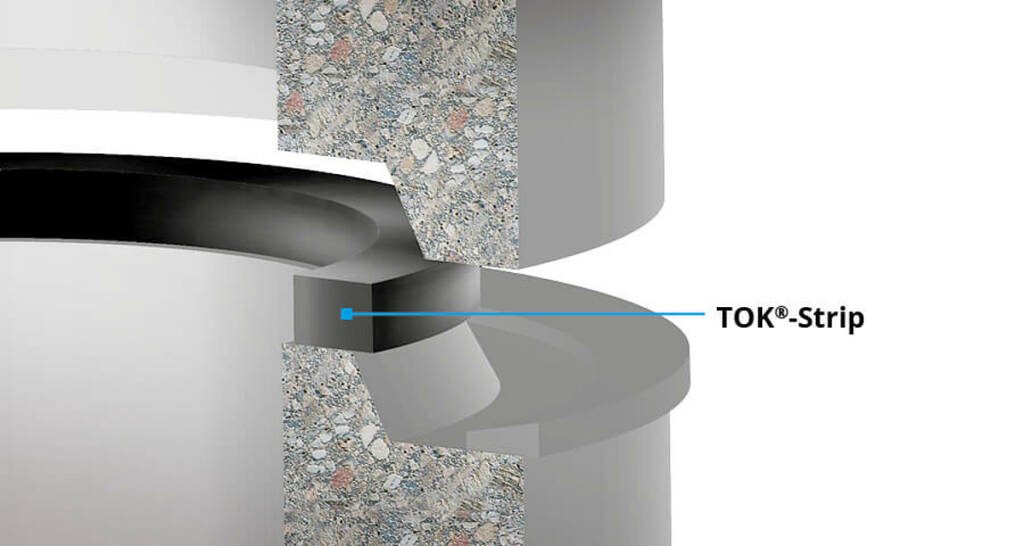

The unique mechanism of hydrophilic waterstops makes them a superior waterproofing solution. When they come into contact with water, the hydrophilic material absorbs the moisture and expands. This expansion exerts outward pressure on the surrounding concrete. The pressure creates a tight compression seal that blocks water passage even under pressure. The expansion capability can be up to 200% of the original volume.

Applications of Hydrophilic Waterstops

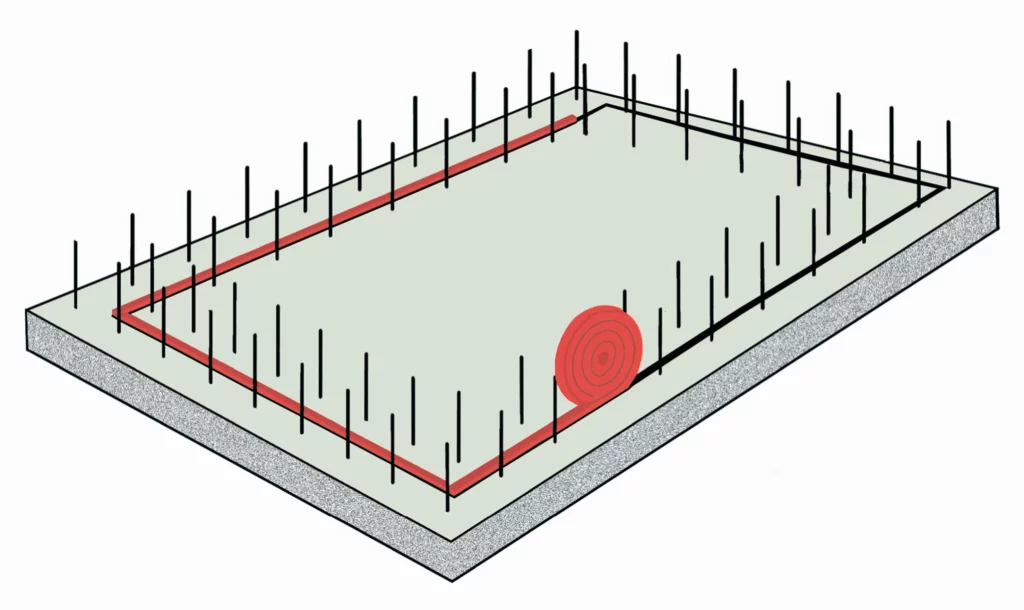

Hydrophilic waterstops are ideal for waterproofing construction joints in below-grade structures. Some typical applications include:

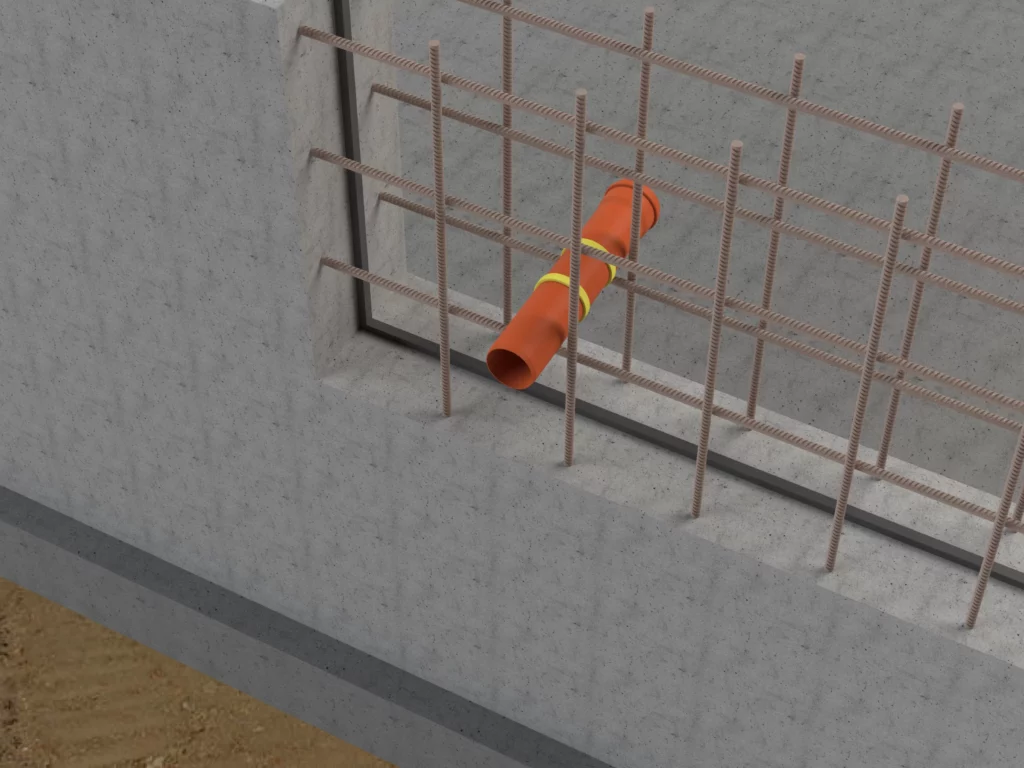

- Floor slab to wall joints – One of the most common use cases. The waterstop seals the joint between the slab and rising wall.

- Wall to wall joints – Used in basements and water retaining structures for sealing wall intersections.

- Wall to ceiling joints – Applicable for overhead joints prone to moisture ingress.

Our hydrophilic waterstops are engineered to suit joints prone to variable water levels. They can seal both pressurised and non-pressurised water ingress. The hydrophilic material retains flexibility after expansion, permitting joint movement.

How to Install of Hydrophilic Waterstops

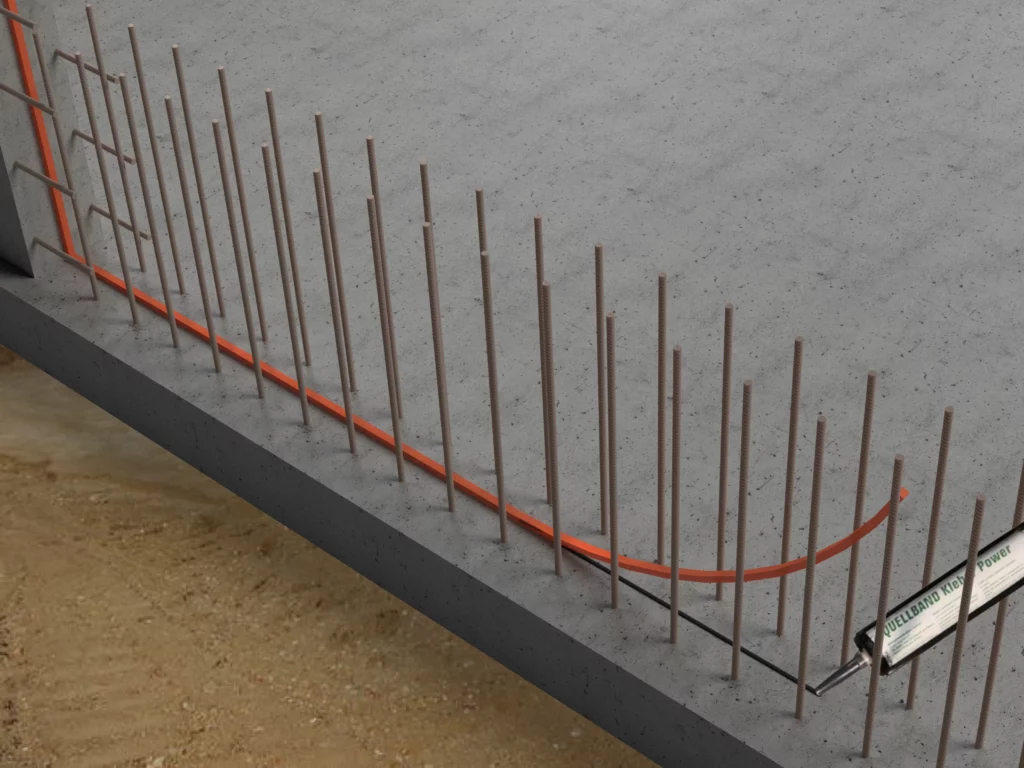

Correct installation is vital for the waterstops to function as intended. Here are some best practices:

- Position the waterstop centrally in the joint and fix it to the hardened concrete. Use swelling tape adhesive or bentonite nail grids to anchor firmly.

- Butt join at corners and intersections to ensure a continuous seal around the structure.

- Ensure ≥80mm concrete cover around the waterstop. This prevents premature swelling.

- Avoid damage during concreting. Use a connection mix and carefully compact near the waterstop.

- Inspect before closing formwork. Replace any swollen or damaged sections.

Certifications for Hydrophilic Waterstops

SDG hydrophilic waterstops hold the General Construction Supervisory Approval (abP) certifying their efficacy. The approval defines the sanctioned scope of use as per type of water exposure. We offer variants approved for variable water level zones – critical for structures seeing intermittent wet/dry cycles.

Reliable Waterproofing Solutions

With decades of application expertise, we provide reliable waterstop systems. Our range offers durable waterproofing, especially for complex joint geometries prone to leakage. Talk to our technical experts about integrating certified hydrophilic waterstops into your waterproofing plan.

For our full range of Construction Waterstops [CLICK HERE]

Share this post