SDG Precast Accessories: A Guide for Manufacturers

SDG is a leading supplier of concrete precast accessories, offering products that improve safety and cost-effectiveness in precast production, lifting, fixing, and connecting.

The SDG product range focuses on high quality magnetic formwork systems, double walling accessories, plastic spacers, and lifting & fixing systems to serve the needs of the precast concrete industry. By providing reliable, economical solutions, SDG aims to advance precast concrete construction in the areas most essential: safety of lifting, and precise assembly.

In this guide, we’ll talk about some common precast accessories as well as discuss some of the potential benefits you might see from using them on your next project.

What are Precast Magnetic Systems?

In the world of precast concrete production, the use of BT Innovation innovative products such as shuttering magnets MagFly® AP, shuttering support systems Multiform, magnetic formers, nailing plates and chamfers have become increasingly prevalent. These magnets, play a vital role during the manufacturing process of precast concrete elements. With advancements in technology and materials, these magnets offer unparalleled holding force-to-mass ratios, revolutionising the precast industry by enhancing both efficiency and safety.

What accessories are available for Double Wall Precast Concrete Sandwich Panels?

Double wall precast concrete sandwich panels consist of two concrete shells separated by an insulated void. Holding these sandwich panels together requires specialised precast accessories that maintain structural integrity and thermal performance. While steel trusses can connect the shells, they can create undesirable thermal bridges, reducing insulation efficiency. Instead, fiberglass double wall connectors like ThermoPin anchors eliminate this issue by preserving the continuity of insulation. Other accessories like double wall anchors, dowels, and DWAK Rockets spacers serve critical functions in transporting, bracing, and manufacturing double wall panels. With specialised products for handling, connecting, and producing, SDG offer the necessary accessories for effective double wall precast construction.

What precast accessories are used for connecting precast wall and floor slabs?

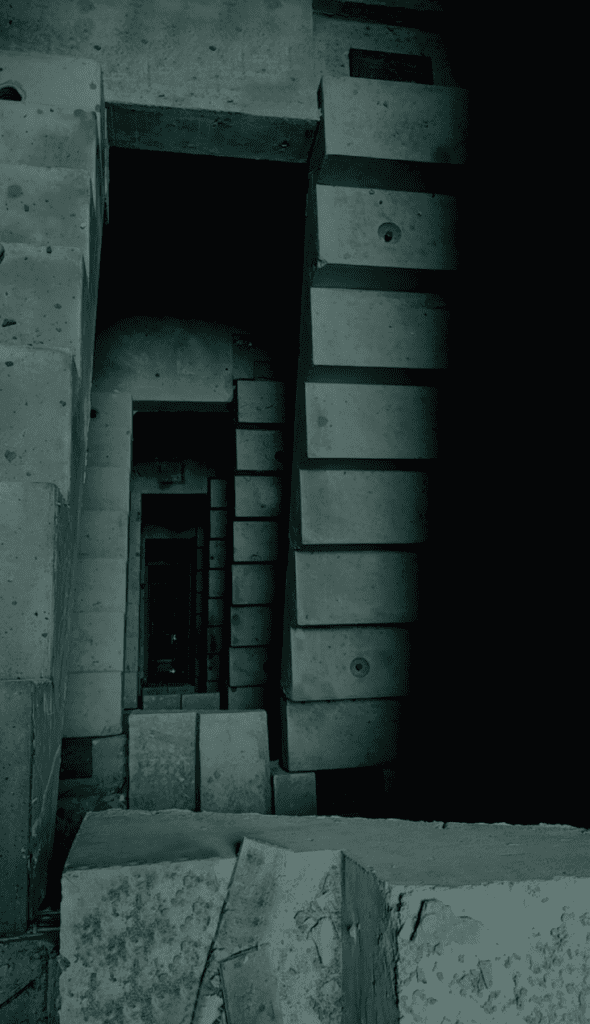

Precast wall and floor slab connections are critical for ensuring structural stability in precast construction. These connections link precast wall panels to each other and to floor slabs.

Common precast connection systems for connecting walls include PVL loop boxes and loop rails, cast into panels, after removing the formwork, the cover is removed, the loops are opened, and a vertical rebar installed into loops. BT-Spannschloss turnbuckles also efficiently connect precast walls while enabling precise assembly.

With robust products for joining wall to wall or walls to floors, SDG offer reliable precast structural connections to unite building components into an integrated structure. Careful design and installation of these accessories creates durable precast buildings to safely withstand loading.

What options are available for lifting precast concrete panels?

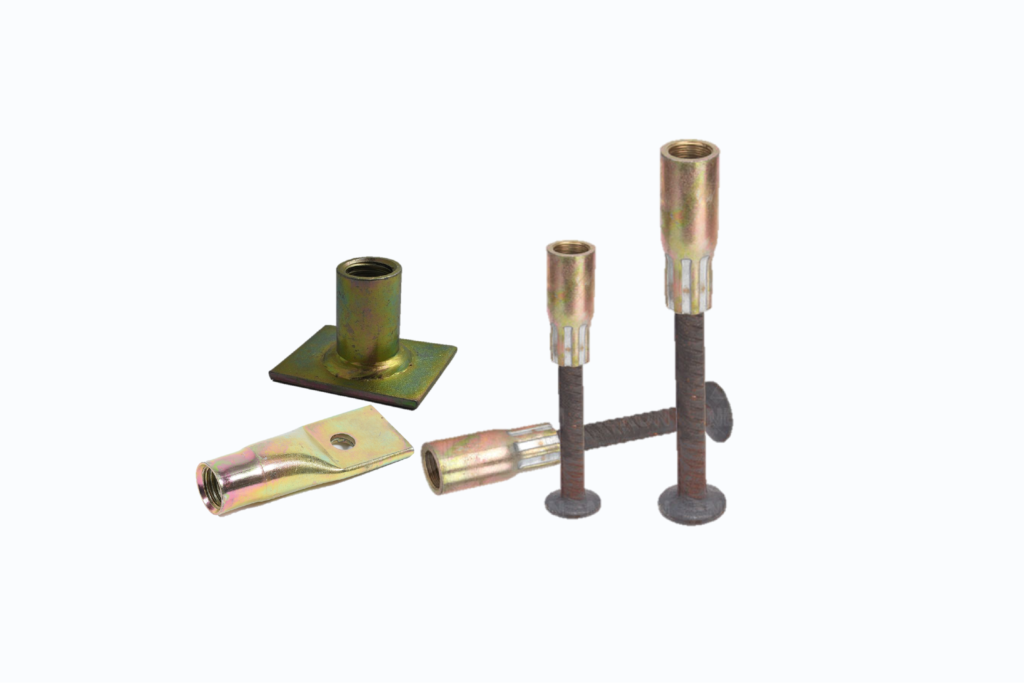

SDG offer a range of precast lifting and fixing systems designed for safe and efficient handling of precast concrete elements during construction. These systems consist of lifting anchors or inserts, which are cast into precast elements.

It is unwise to lift concrete without a completely co-ordinated lifting system which has been developed and tested by a specialist. The basis of precast lifting system is a special cast-in anchor which is easy to install in the precast yard and easy to operate in transport and on site.

SDG provides three specialised lifting systems for manoeuvring precast concrete:

Socket Lifting System

The Threaded Socket System uses conventionally threaded parts for adjustable lifting and anchorage of panels. With socket safe working loads from 500kg to 12500kg, it enables lifting diverse concrete elements from beams to walls. Multiple socket types allow manufacture and installation of panels with demoulding, loading, and tilting.

Lifting With Spread Anchor System

The Spread Anchor System is an industrial scale solution for high-capacity repeated handling. Quick action clutches from 0.7t to 22t simplify connections, prevent mismatches, and uniquely flip very narrow solid and insulated wall panels.

Spherical Anchor Lifting Systems

Spherical Anchor Systems efficiently manoeuvre precast units of varying sizes with an easy engage and release mechanism. This rapid attachment system enhances productivity, especially for repetitive positioning tasks.

From standard threaded connections to heavy-duty spherical anchors, SDG’s range of tested lifters provides adjustable and reliable solutions tailored to common precast handling needs. Their systems enhance safety and efficiency throughout the precast process.

The use of plastic precast spacers in precast concrete production

Plastic spacers serve a vital function in precast concrete manufacturing. Precast requires maintaining strict concrete cover over reinforcement steel per code requirements. Plastic’s versatility adapts spacers to the diversity of precast elements and directions of support. Spacers centrally position rebar within moulds before pouring, whether in vertical or horizontal orientation. This ensures proper spacing that prevents defects from inadequate cover. With characteristics suiting an array of specific precast applications, plastic spacers align steel exactly as needed prior to concrete placement. Their adaptable performance and durability under wet concrete conditions drive extensive use for achieving quality in precast construction.

Spiral tubing for precast production

Galvanised Spiral Tubing is used for diverse applications in both precast and cast-insitu concrete projects. Tailored to facilitate precast connections, service penetrations, and the creation of formers for starter bars and post-tensioning ducts. These robust metal ducts allow for effortless casting into concrete, providing a seamless integration that can be securely tied into position alongside the reinforcing steel.

At SDG we pride ourselves in having the precast accessories and technical advice you need for your project. Call us today or have a look at our extensive range of precast products by clicking here.

Share this post