A6 RANDALSTOWN TO CASTLEDAWSON

Case Studies / A6 RANDALSTOWN TO CASTLEDAWSON

Main contractor:

Graham Farrans JV

Engineer:

Roughan & O’Donovan / ARUP

Date:

November 2020

PROJECT SUMMARY

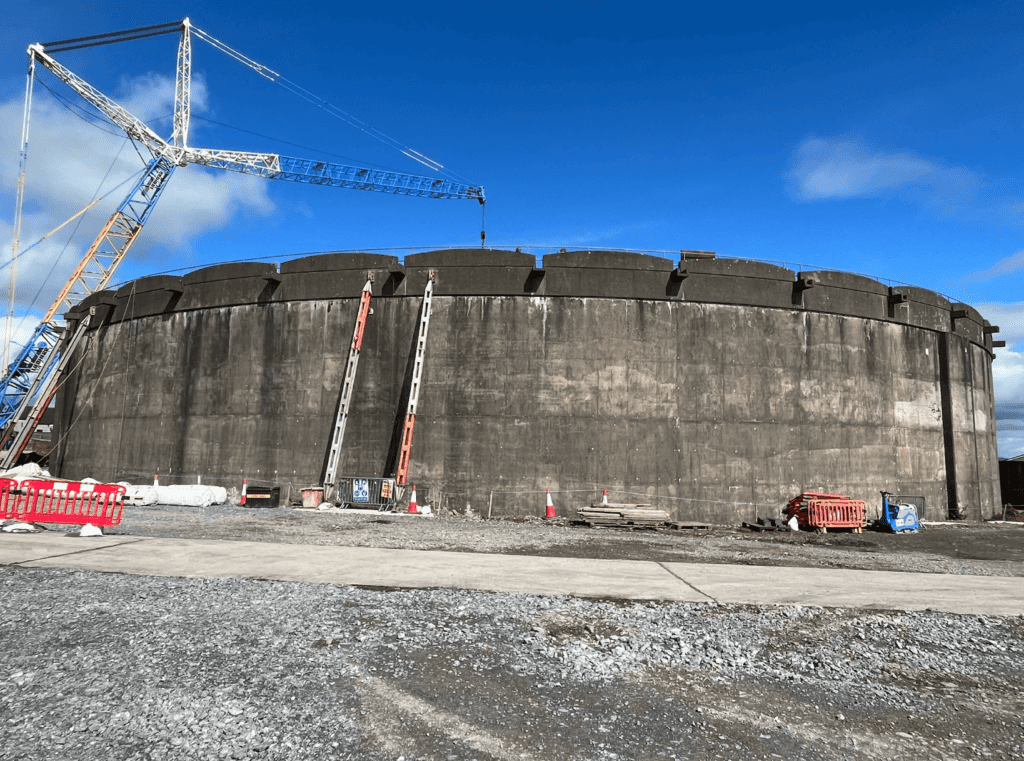

SDG was a proud supplier to the £189m A6 Randalstown to Castledawson scheme. The scheme comprised of over 14.7km of dual carriageway, including a 7.4km section between Toome and Castledawson, and a 7.3km section between Randalstown and Toome, each connected by the Toome Bypass.

Our core areas of supplies were bridge bearings, waterproofing materials, and construction accessories. With over 70 structures throughout, the project was a huge undertaking for the site team. The 70 structures included 11 overbridges, 4 footbridges, a river bridge, 5 underpasses, and over 50 culverts.

THE CHALLENGE

This phase of the A6 now plays a vital part in making for an efficient transport route from North-West Belfast to the North-East. The existing road network carries approximately 15,000 cars per day,

with the figure set to grow in the coming years. The Department of Infrastructures investment in this project will greatly improve road safety and journey times by reducing congestion.

OUR SOLUTION

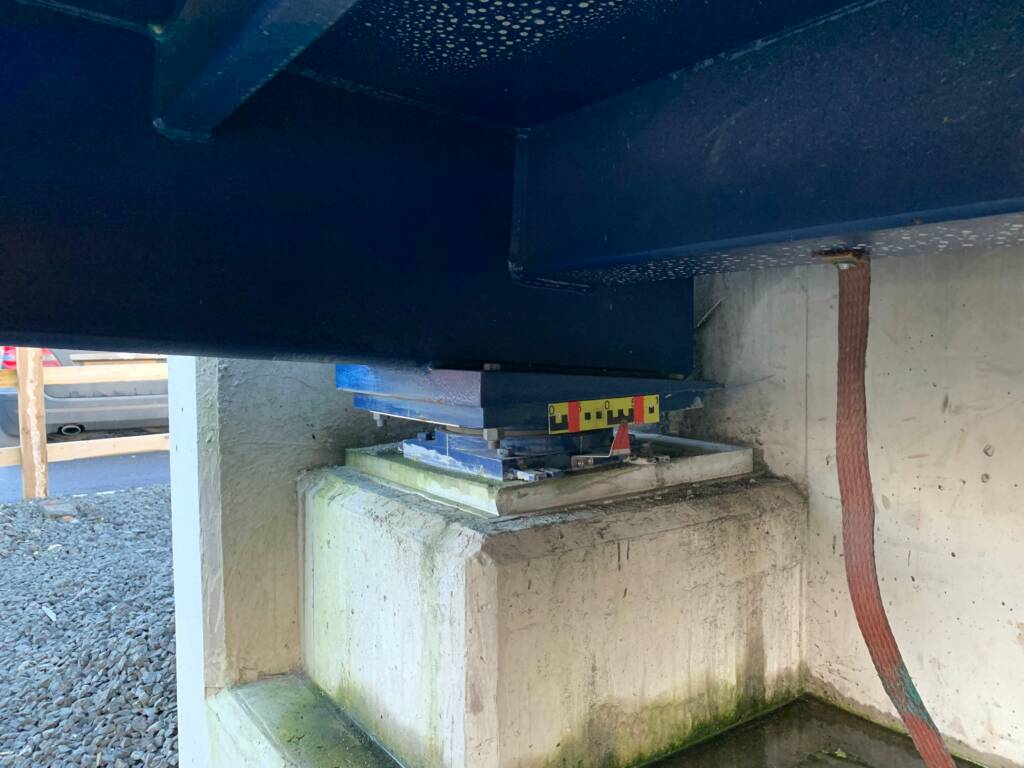

SDG worked closely with Manufacturer GUMBA based in Germany to design and supply a total of over 60 Guided, Free and Fixed Pot and Elastomeric Bearings in accordance with EN 1337-5. Pot Bearings are a well-proven bearing type, their industry standing has been achieved through the combination of a non-reinforced elastomeric bearing (Natural Rubber) confined within a closed steel housing.

With Pot Bearings, it is possible to transmit high vertical loads on a very small area. A great example of this can be seen in the River Bann Project, where a load of over 1500kN needed to be transmitted – find out more.

THE RESULTS

SDG’s knowledge and experience were valued throughout the project, with pre and post-installation site visits to ensure the installation was in accordance with the design and manufacturer’s installation process.

Site teams were happy with the fast turnaround on the supply of the bearings, preventing delays to any bridge installation and the overall project completion.

Share this post