TARANTO PRECAST – BT THERMOPIN

Case Studies / TARANTO PRECAST – BT THERMOPIN

Main contractor

Taranto Precast

PROJECT SUMMARY

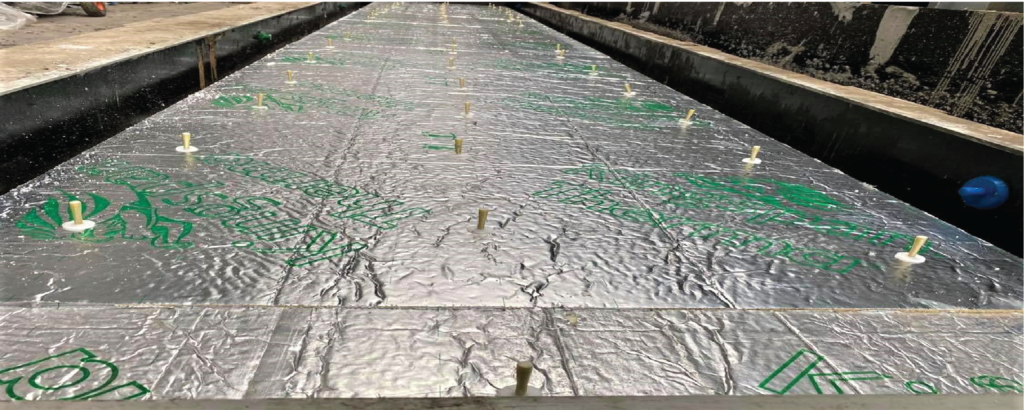

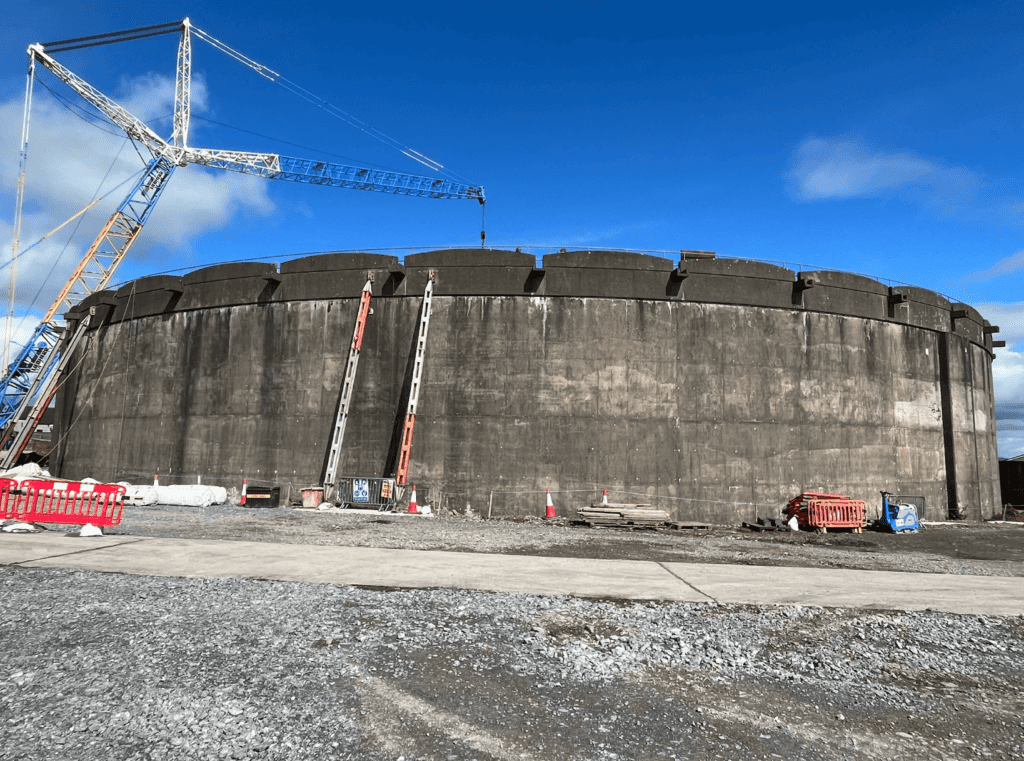

SDG are proud to have worked with Taranto Precast on the supply of the BT ThermoPin secure anchoring system, which was recently designed into their sandwich panels for a large scale distribution centre project.

Working closely with SDG, Taranto were able to efficiently add the ThermoPin into their existing designs. The drawings were analysed and marked up

by BT Innovation whose team of engineers determined the pin size, quantity, and exact layout. At SDG we always aim for a 48- hour turnaround on productions of drawings, and achieve a same day turnaround in 60% of cases.

On the BT ThermoPin, Taranto’s Design Manager commented: – “The BT ThermoPin was a simple for choice us. We can use less per SQM than market alternatives, meaning less material and subsequently less overall cost to our programme. The assistance with design for us is imperative, it frees us up to concentrate on other aspects of production whilst giving us assurances that our designs are more than sufficient.

We are very happy with the innovative solutions that SDG continue to provide us with consistently.

The BT ThermoPin securing anchor system is a glass fibre reinforced polymer (GFRP) connecting anchor for sandwich walls and core insulted double wall panels.

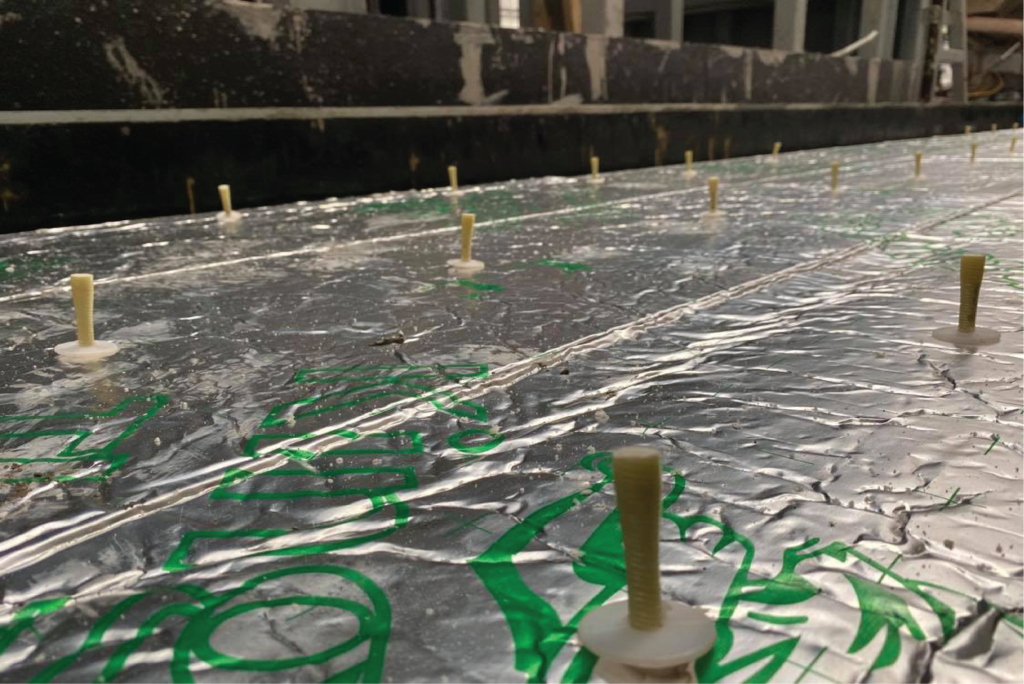

ThermoPin is used to connect facing and load-bearing layers within core-insulated concrete panels. The strong GFRP material is suitable for use in narrow structural elements, allowing for the ultimate level of design versatility. Thanks to the attached cap, the bar slides smoothly into fresh concrete, ensuring a fast assembly.

The fixed plastic ring guarantees correct installation and ensures that the fastening point in the insulation is sealed fully. As a result, the installed bar is fully beneath the surface of the concrete, and not visible from the surface.

The result of this innovative design is a prefect surface without visible flaws. ThermoPin features conical openings at each end to increase pull out resistance. A high tensile strength is achieved through the use of continuous intact strands of glass fibre along the axis of the rod.

The advantages of ThermoPin at a glance:

– Low assembly costs due to fast and simple installation

– Durability – proven stability in alkaline materials

– Thin – structures with a low layer thickness are possible

Share this post